PULSAIR® – Variable AIR PULSING in one single duct

AIR PULSING is a unique alternative solution to classical air DIFFUSION. For many years – and even today – many variants have been implemented, but they always remain too constraining for both installation technicians and engineering departments (see CLASSICAL AIR PULSING below). This is why today PULS’AIR® proposes VARIABLE AIR PULSING in one single duct with GUARANTEED RESULTS and no significant loss of AIR PULSING efficiency.

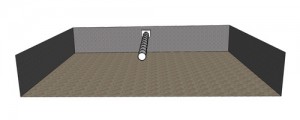

PULS’AIR® + SUNAAL®

THE SOLUTION TO ADOPT

One single PULSAIR® duct with speed controller. Ensures temperature uniformity and control over residual air speeds. PULSAIR® gives its clients a commitment to guaranteed results for all its AIR PULSING technology installations.

No AIR PULSING efficiency deterioration with the « PULS’AIR® + SUNAAL® » system..

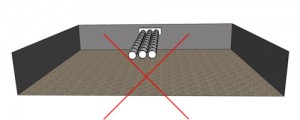

CLASSICAL AIR PULSING

THE INSTALLATION TO AVOID

Requires 2 to 3 ducts + plenum box + registers.

Difficult to regulate.

Complex Winter / Summer mode management.

Installation can only work with motorised registers.

Very large ducting lengths.

Installation times multiplied by three!

Very high overall installation costs.

Several factors come into play when defining a PULS’AIR® duct, including:

- Purpose of the conditioned premises

- Dimensional characteristics of the conditioned space

- Power to deliver

- Energy rating of the installation

The combination of these factors (and the duct’s positioning) will determine several parameters for selecting the PULS’AIR® duct, in particular:

- Duct diameter, which affects air speed inside the duct and hence determines which type of pulsing to use (tangential or coaxial).

- Range, and hence the primary inlet diameter (which determines how far the air mass is to be expelled).

- Residual speed and angle of thrust.

- Quantity of air set in motion (varies depending on the type of activity the premises are used for), hence the secondary outlet characteristics.

- Flowrate per linear metre

PULS’AIR® installations can today offer real energy savings without significantly compromising on AIR PULSING efficiency.

Tangential or coaxial pulsing (inclination of the jet) is a function of two components: air speed inside the duct and exit speed from the hole. A PULS’AIR® duct is thus selected in accordance with a number of criteria, as explained above. Some of these criteria are determined mathematically, others by knowledge and mastery of pulsing technology.

It is only after the combination of these two selection stages that we perform the final operation: inserting the input data into the SUNAAL® perforation pattern mathematical modelling tool developed by PULS’AIR®.

SUNAAL® then defines the perforation pattern that will yield the required characteristics.

Product characteristics

The range of PULS’AIR® perforated metal ducts or AIR PULSING Metal Ducts (PMD) covers diameters from 200 mm to 1,700 mm in 1.5 m lengths.

We market ducts delivered closed (ready for installation) or open lengths in interlocking sections packaged on a pallet.

Each length section is terminated by a turned-out edge for assembly into one piece by sleeves.

Our perforated ducts are available in all materials and all RAL colours.

The ducts find application in all fields of activity (swimming pools, theatres, function rooms, retail outlets, airports, halls, industry, sports centres, hangars …).

Product ranges

Standard Range

1. Carriage paid

2. 20-year guarantee on equipment

3. Closed ducts, ready for installation on site

Eco Range

1. Carriage paid

2. 20-year guarantee on equipment

3. Ducts delivered open

MAIN ADVANTAGES:

- Low production costs (nationally based, designed and produced)

- Aesthetically pleasing ducts (laser perforations)

- 30 – 50% assembly time reduction thanks to 1.5 m length sections

- 35 years’ cumulated experience in air diffusion and air pulsing

- Assistance in duct design / configuration / dimensioning

- 2 – 5 week delivery time (depending on size of site)

- Reduced assembly time with ducts delivered closed

- Choice of different possible materials and RAL colours

- No condensation, no cladding

- No need for take-up circuit

- Temperature uniformity

- No specific maintenance requirement

- Energy savings

- French made

<